E-mail: [email protected]

is possible only with

a professional approach

Our own raw material base allows us to provide low prices

Multi-stage quality control of raw materials and finished products

The work is based on conscientiousness, compliance with deadlines and agreements

Long-term cooperation with you is our main goal

The company “Trend-Living Trade” will manufacture high quality pallets. Well-established in-house production allows us to carry out orders for pallets in large volumes of high quality. We make pallets to order, we use different wood species according to the preferences of the customer. Today we have the adjusted production of:

Pallets to order are manufactured due to the preferences of the customer. We have a large selection of raw materials, our own equipment for its processing. During the work, the wood is processed, and upon completion the certificates of conformity for the products are issued.

Production of pallets to order is our specialty. The experience of craftsmen and high-quality equipment helps to fulfill orders in strict accordance with all standards. Contact us for detailed information and advice on all issues concerning pallet manufacturing. Delivery is made throughout Europe to any region.

Our company operates in the industrial packaging market, it has its own production of wooden pallets, we work with a large network of wood suppliers. Therefore, we offer you cooperation in the purchase of your softwood and hardwood timber, namely: square edged sawn timber of the 2nd and 3rd grade GOST 8486-86, GOST 2695-83.

If you have the opportunity and experience in the production of wooden pallets, and are interested in guaranteed sales and long-term cooperation, contact us and we will offer you the most favorable conditions.

The wood used for the manufacture of pallets in quality is not lower than the 2nd grade according to GOST 8486-86 of the following species: spruce, fir, pine. In some cases, it is possible to use birch, beech, ash, maple, oak, alder according to GOST 2695-83. Wood moisture content is no more than 25%.

Assembling is conducted by means of the special spiral or ruff nails GOST 4028-63, providing to the pallet additional durability and maintenance of geometry during its final drying.

If necessary, drying or heat treatment and/or logo application by pokerwork is performed.

Also, according to your desire, additional processing of pallets is carried out, for example: painting pallets in corporate color, grinding, processing with antiseptic, applying the necessary logos by pokerwork.

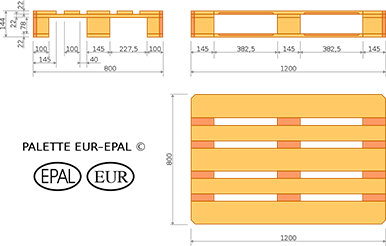

EPAL 1 pallets have the following characteristics. Safe carrying capacity: 1500 kg. Pallet weight about 25 kg. Length is 1200 mm, width is 800 mm, height is 144 mm. According to the standard, deviation from the specified dimensions in width and length by ∓ 3 mm and + 7 mm in height is allowed.

EPAL 1 are made of soft or hard wood boards. You need to find a supplier who will consistently offer you the wood of the desired quality. Spruce, pine, alder or aspen are often used. It is not allowed to manufacture pallets from poplar. The boards should be smooth, without thinning. If you are making a new pallet, then the boards must be new. When repairing a pallet, it is allowed to use old, but good quality boards. Wood moisture content is no more than 22%. 11 boards and 9 bosses are needed to make one pallet.

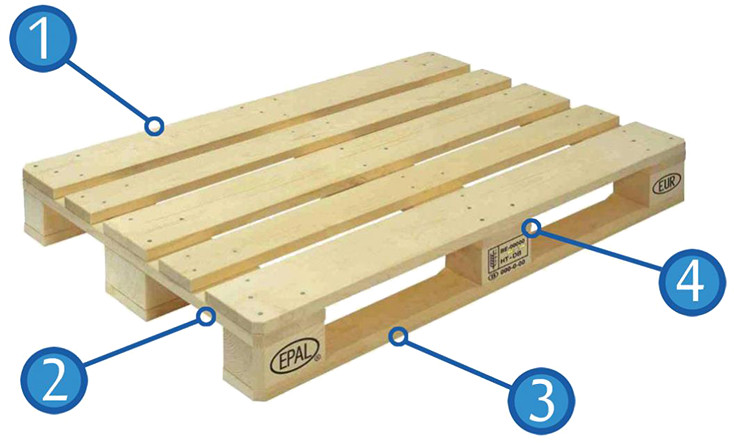

1 – Flooring board

2 – Cross deal

3 – Bottom board

4 – Kevel